High-Performance Crushing. Consistent Results.

Cone crushers play a vital role in achieving high-quality reduction across secondary and tertiary crushing stages. Their performance directly impacts throughput, product shape, and downstream circuit efficiency making engineering accuracy and material reliability essential.

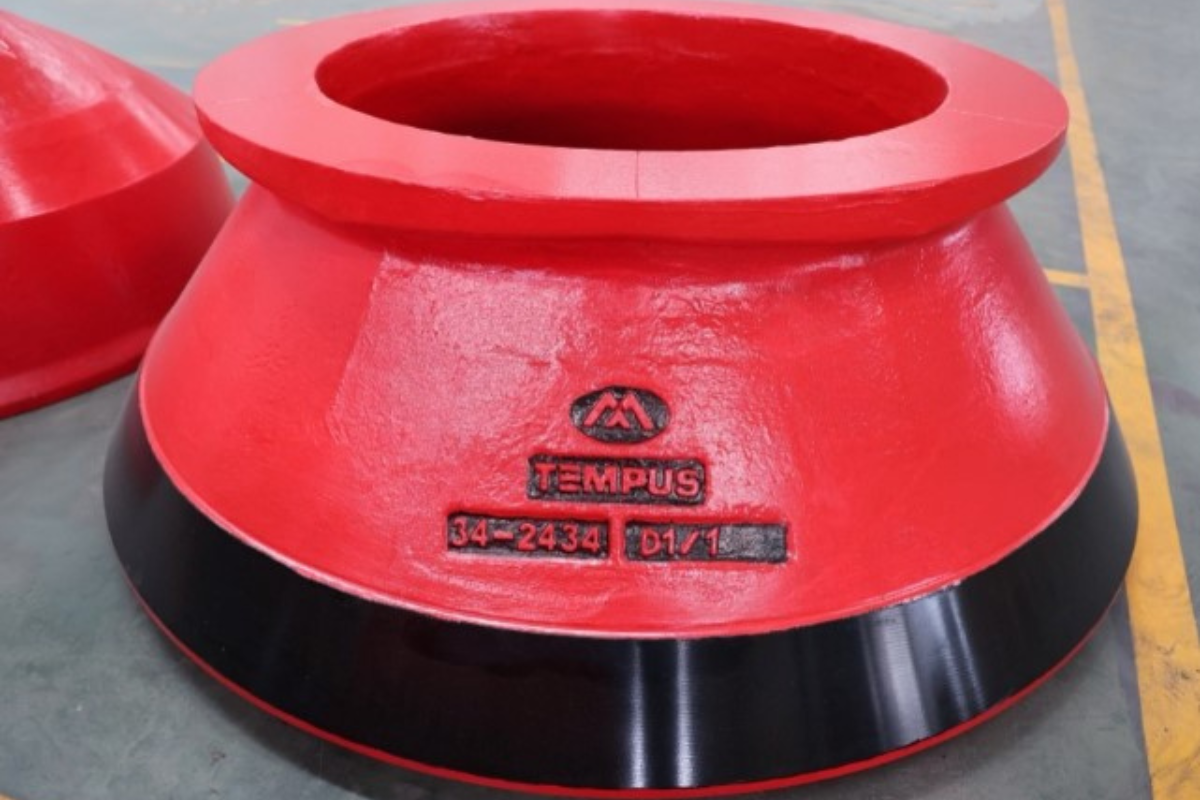

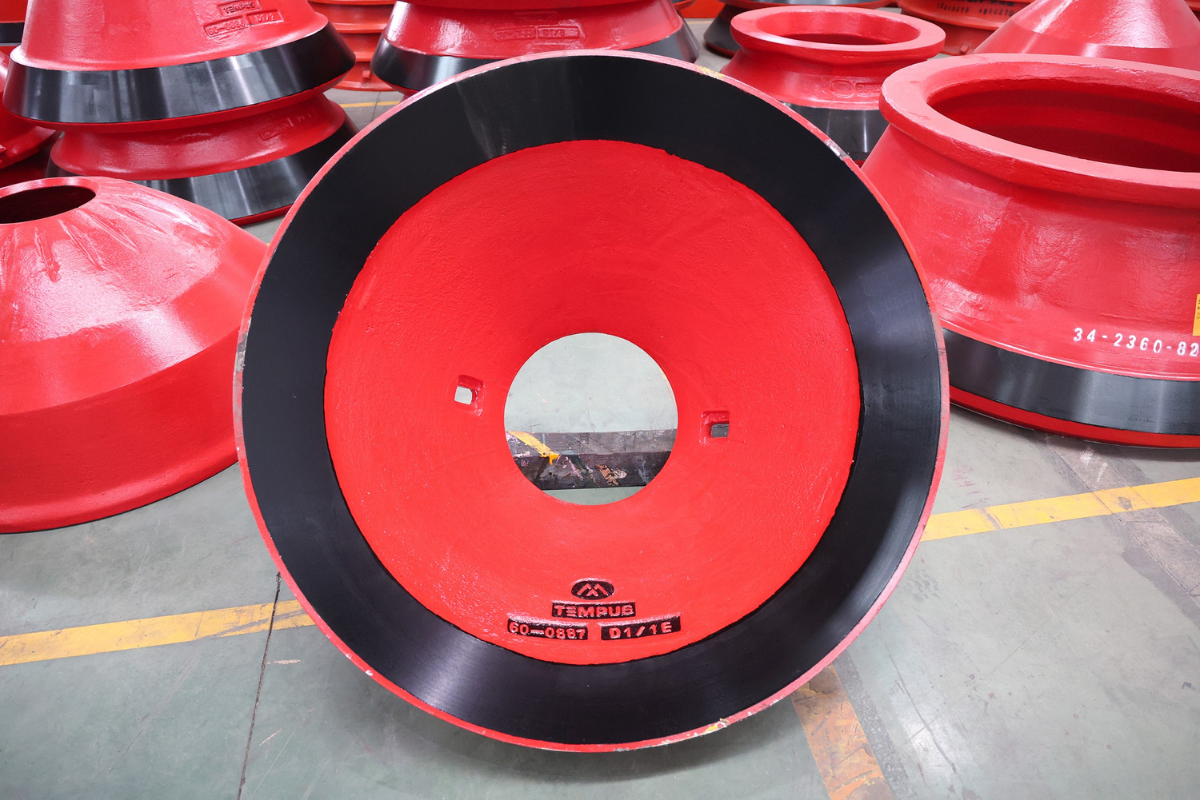

Our cone crusher liners are precision-cast to deliver consistent reduction, superior wear life, and reduced cost per tonne under demanding Australian conditions. Each liner set is profiled to optimise chamber flow and maintain reliable performance throughout its service life.

With decades of experience supporting mining, quarrying, and aggregate operations, Mining Wear Parts provides replacement components and wear liners that keep your crushing equipment operating safely, efficiently, and consistently.

Optimised Crushing Efficiency + Long-Life Wear Liners

Every cone crusher is built to endure extreme conditions from hard rock reduction to abrasive ore. Our liners and components are engineered for reliability, performance, and efficiency under continuous load.

- Consistent product gradation with precision-controlled chamber geometry

- Hydraulic adjustment and tramp release for safe clearing and CSS control

- Optimised speed and chamber design for maximum crushing efficiency

- Heavy-duty bearings and bronze bushings for long service life

- Accessible components for simplified liner changes and maintenance

These features deliver predictable wear life, improved material shape, and lower costs per tonne — helping operations achieve consistent, efficient output even under variable feed conditions.

Read how we helped improve cone crusher performance and liner life at AngloGold Ashanti’s Tropicana site:

View the Tropicana XL900 Case Study

Applications and Capabilities

- Secondary and tertiary crushing in fixed or mobile plants

- Processing of iron ore, gold, copper, and aggregates

- Optimised circuit integration with feeders, conveyors, and screens

- High-capacity operations requiring predictable output and minimal downtime

Designed to perform under high impact and abrasive conditions, our liners ensure consistent reduction, improved particle shape, and lower maintenance across a wide range of site conditions.

Wear Parts & Components Supplied

Mining Wear Parts supplies a complete range of replacement wear parts and components to support all HC Series and compatible OEM cone crushers.

- Mantles, concaves, and feed cones

- Eccentric bushes, main shafts, and countershafts

- Head nuts, torch rings, and bolts

- Hydraulic assemblies, seal kits, and tramp release cylinders

- Adjustment rings, bowls, and frames

All components are precision-cast using high-quality manganese and chrome alloys for superior strength, reliable fitment, and extended wear life under heavy-load conditions.

Through design optimisation and chamber analysis, we’ve achieved significant improvements in liner life and crusher performance across multiple Australian sites.

Performance Testing and Quality Assurance

All cone crusher liners are precision-cast and validated to meet or exceed OEM tolerances. We perform metallurgical testing, chamber geometry verification, and hardness profiling to ensure every liner achieves optimal reduction and long-term wear balance.

- Metallurgical composition and heat treatment verification

- 3D profile scanning and chamber mapping

- Fitment inspections and on-site performance reviews

Our quality assurance program guarantees consistency, reliability, and predictable liner life across all cone crusher models we support.

Compatible Crusher Models

Our cone crusher liners and components are compatible with leading OEM brands and models, including:

| Make | Cone Crusher Models |

|---|---|

| Atlas Copco | PC Series: PC1000 |

| FLSmidth | Raptor cone crusher series |

| Kawasaki / Kobe | CYBAS, GYRADISC, ZI-Cone series |

| Kue-Ken | CT-series cone crushers |

| McCloskey | C2, C2R, C3, C3R, C4 cone crusher series |

| Metso / Nordberg | HP, GP, MP, Omnicone series |

| Parker | Parker cone crusher models |

| Pegson | Autocone & Automax: 900, 1000, 1300 |

| Powerscreen | 1000, 1150, 1300 Maxtrak |

| Sandvik | CH, CS, and mobile tracked cones |

| Sandvik / Extec | Extec X-series & SBS-style |

| Svedala | Hydrocone & Superior series |

| Symons | 2ft–7ft Standard & Short-Head |

| Telsmith | Gyrasphere: 24S–66S |

| Trio | TC & TP series |

| Terex | TGS series |

| Terex / Cedarapids | MVP & RC series |

| Terex / Finlay | C-series (C-1540 etc.) |

| Thyssenkrupp | Kubria series |

| Other OEMs | Additional designs on request |

Get in Touch

Need help selecting the right part? Our local team can assist with compatibility, fitment, and site-specific recommendations. Complete the form below and we’ll get back to you shortly.